The quick answer

Maximo Thermo (thermally modified hardwoods and softwoods) is optimised for dimensional stability, decay resistance, and a uniform, rich tone.

Cedar (typically Western Red Cedar or similar) is a naturally durable, lightweight, aromatic wood with good stability and a familiar, traditional look.

Which is better for a ceiling depends on what you value:

- Ultimate stability + uniform tone → Maximo Thermo

- Natural aroma, grain, and classic warmth → Cedar

Technical comparison

Property

Maximo Thermo (thermally modified wood)

Cedar (e.g. Western Red Cedar)

Material Type

Thermally modified wood (e.g., Ayous, Ash, Radiata Pine, Scots Pine)

Naturally durable softwood (Thuja plicata or similar)

Typical density

Moderate; slightly reduced from untreated wood due to thermal process (~510 kg/m³ avg)

Low to moderate — lightweight (ideal for ceilings)

Dimensional stability

Very high — reduced EMC leads to minimal swelling/shrinkage

Good — stable vs. most softwoods, but less so than thermo wood

Moisture uptake / EMC

Very low — 3–5% EMC at 65% RH, 20°C

Moderate — generally low for softwoods, but higher than thermo

Decay / rot resistance

Very high — Durability Class 1–2 depending on species (EN 350)

Very high — naturally resistant to decay and insects

Durability class

Class 1–2 (EN 350)

Class 2 (durable), naturally resistant

Warranty

20-year Warranty

Not available

Strength (bending/stiffness)

Slightly reduced from original species due to heat modification (not an issue for ceilings)

Typical softwood strength — adequate for non-structural uses

Janka hardness

Low-to-moderate (softwood range)

Low (softwood)

Workability

Excellent — machines well, pre-drilling recommended near edges

Good— easy to saw, plane, and fasten

Surface finish & colour

Even, rich caramel to chocolate brown; darkens with treatment

Reddish-brown to pale honey tones with natural variation

Stain/paint acceptance

Takes oils and coatings well; surface prep may be needed

Accepts oils and stains well; tannins may affect coatings

Fastener holding

Good — pre-drill for thin profiles or near ends

Good — pre-drilling recommended near edges

Thermal conductivity

Comparable to softwoods (~0.12 W/m∙K)

Similar; lightweight helps insulation performance

Acoustic behaviour

Dense boards reduce creaks; works well with insulation

Slightly more absorbent due to lower density

Fire performance

Class B–C (varies by species); combustible unless treated

Class C— combustible;

Maintenance

Low — will silver if uncoated; surface stays stable

Low–moderate — periodic oiling to maintain appearance

Expected lifespan (indoors)

Decades — highly stable in interior conditions

Decades — long-lasting when kept dry

Relative cost

Mid-range; lower than some premium cedar grades

Mid–high depending on grade/source

Sustainability

Sourced from plantation-grown or FSC®-certified forests

Available from certified sources; varies by region

Best use case (ceilings)

Sleek, uniform ceilings in humidity-variable rooms

Sustainability

Key Technical Notes

Thermal modification (MaximoThermo)

- Heat and steam used in a low-oxygen environment.

- Alters the wood at the cellular level: reduced sugars and EMC → improved stability and decay resistance.

- Strength decreases slightly, but irrelevant for ceiling use.

Cedar’s natural strengths

- High in natural oils and extractives.

- Naturally rot- and insect-resistant.

- Lightweight and easy to work with.

Cedar’s natural strengths

Moisture & Movement

- MaximoThermo has 3–5% EMC — less prone to cupping/gapping in humid spaces (bathrooms, kitchens).

- Cedar still performs well but may move more with RH swings.

Strength vs Stability Tradeoff

- Heat-treated wood may lose some bending strength.

- Not an issue for ceilings — they are non-structural.

- Always follow manufacturer guidelines for board thickness and fastener spacing.

Fastening and Fixes

- Use stainless steel or coated screws.

- Pre-drill near ends or knots for both materials.

- Hidden fasteners = clean look. Face-screws + plugs = traditional look.

Installation Tips for Ceilings

- Acclimate boards for 48–72 hrs in room conditions.

- Install over level battens or furring strips.

- Pre-drill for thin profiles or tight fastener zones.

- Seal back and ends to balance moisture exposure.

- Follow fire safety rules for lights, especially recessed fixtures.

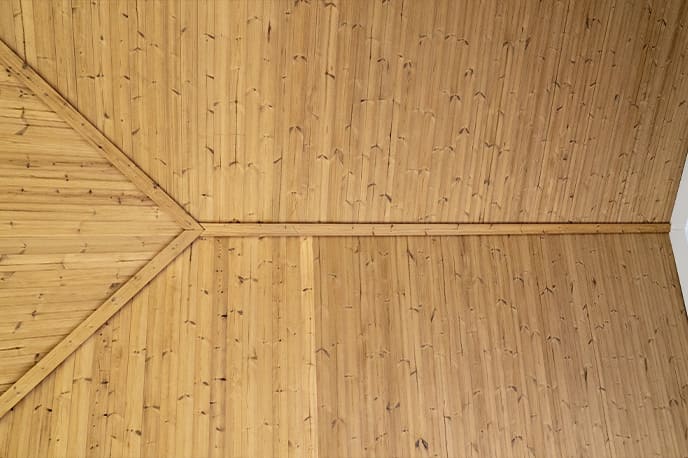

Finish, Aging & Appearance

MaximoThermo:

- Dark, even tone out of the box.

- Accepts oils and coatings well.

- UV will cause gradual greying if exposed to light.

Cedar:

- Warm, natural look.

- Ages to silver-grey if unfinished.

- Oiling preserves tone; UV-stable finishes reduce greying.

Fire & Code Considerations

- Both are combustible materials.

- For public buildings or multifamily homes, check local code.

- Fire-retardant coatings are available — may alter look or cost.

Acoustic & Thermal Behaviour

- Wood ceilings help dampen sound in mid–high frequencies.

- Cedar is slightly better at softening sound due to lower density.

- Add insulation above for better control — species alone won’t fix acoustics.

Sustainability

- Maximo Thermo species (Ayous, Ash, Radiata Pine, Scots Pine) are plantation-grown or responsibly harvested.

- FSC/PEFC certification recommended.

- Cedar: availability of old-growth is limited — choose certified sources.

Pros & Cons — Quick View

MaximoThermo

✅ Ultra-stable in humidity

✅ Uniform dark tone

✅ High decay resistance

✅ Low maintenance

✅ 20-Year Warranty

⚠ Slightly lower strength (non-issue for ceilings)

⚠ Less natural grain/aesthetic variation

Cedar

✅ Natural aroma and warmth

✅ Lightweight and easy to work

✅ Classic appearance

⚠ More movement

⚠ More variation (if uniformity is desired)

⚠ Premium grades can be expensive

Which to Choose — Practical Scenarios

Choose MaximoThermo if:

- You’re building in humid or high-RH environments (bathrooms, kitchens).

- You want a uniform, darker tone.

- You value stability and low maintenance over rustic character.

Choose Cedar if:

- You want natural aroma, knots, and visible grain.

- You prefer a lighter-weight board that’s easy to handle.

- You want a traditional, warm aesthetic.

Short Spec Checklist for Contractors

- Board thickness: 12–21 mm typical (verify with product sheet)

- Fasteners: Stainless or coated; spacing as per spec

- Acclimation: 48–72 hrs indoors before install

- Finish: Seal backs + faces before install

- Expansion gaps: 3–6 mm ends/joints (less with Thermo, but don’t skip)

- Fire: Check plenum/fire codes for ceiling cavities